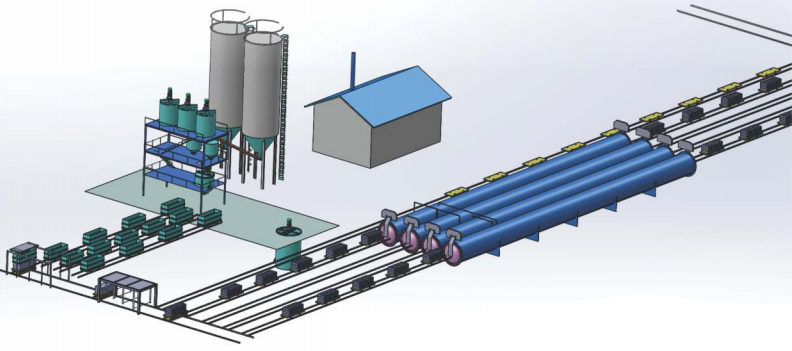

AAC Block Making Plants, AAC Plant, Autoclave Aerated Concrete Block Making Plants, Turnkey Projects, Manufacturer, Exporter, Supplier. Our setup is situated at Pune, Maharashtra, India

AAC Block making plant is a highly thermally insulating concrete-based material used for both internal and external construction. Besides AAC's insulating capability, one of its advantages in construction is its quick and easy installation, because the material can be routed.

AAC is well suited for urban areas with high rise buildings and those with high temperature variations. Due to its lower density, high rise buildings constructed using AAC require less steel and concrete.

Autoclaved aerated concrete is cured in an autoclave - a large pressure vessel. In aircrete production the autoclave is normally a steel tube some 1.6 meter in diameter and 31 meters long. Steam is fed into the autoclave at high pressure, typically reaching a pressure of 800 kPa and a temperature of 180 oC.

The autoclaved aerated concrete production process differs slightly between individual production plants but the principles are similar. We will assume a mix that contains cement, lime and sand; these are mixed to form a slurry. Also present in the slurry is fine aluminum powder - this is added to produce the cellular structure. The density of the final block can be varied by changing the amount of aluminum powder in the mix.

We are offering our clients wide range of AAC block, Manufactured as per the international standards. The products are fabricated using the high grade raw materials. Our products are highly demanded in the industry for their superior quality. Autoclave Aerated Concrete (AAC) is used in construction projects across the world, and produced from Five basic raw material Fly ash, Sand, lime, gypsum, Aluminum powder and water combined with an expanding agent.

Maximum Block Size in MM :

- L 600 X W 200 X H 100

- L 600 X W 200 X H 125

- L 600 X W 200 X H 150

- L 600 X W 200 X H 200

- L 230 X W 110 X H 75

- No. of Block Per Cubic Meter : As Per Block Size

- Density of AAC Block : 650 - 700 kg / m3

- Compressive Strength : 30 - 35 kg / cm2

- Thermal Conductivity : 0.24

- Production Capacity Per Day : 50 / 75 / 100 / 150 / 200 Cubic meter / 24 hrs

- Feeding of Raw Material : Automatic

- Man Power : 7 to 8

- Electrical Power Connection : 65Hp

Building, Hospital, Could storage, Education Institutes Construction, Office Building, Multi - family projects, Single family project, Auditorium & Theaters